Plasma Cutting Services

Great Customer Service | Over 50 Years of Experience | Locally Owned

Great Customer Service

Over 50 Years of Experience

Locally Owned

What is Plasma Cutting?

Plasma cutters work by sending an electric arc through a gas that is passing through a constricted opening. The gas can be shop air, nitrogen, argon, oxygen, etc. This elevates the temperature of the gas to the point that it enters a fourth state of matter called plasma. Contact

Bear Steel Inc for your next project.

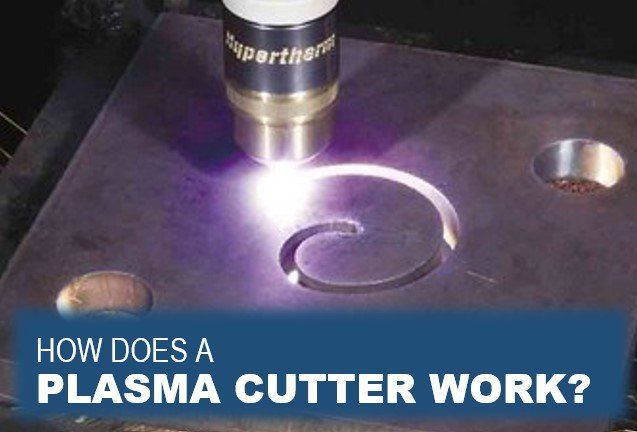

How Does a Plasma Cutter Work

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass, and copper as well as other conductive metals. Plasma cutting is often used in fabrication shops, automotive repair and restoration, industrial construction, and salvage and scrapping operations. Due to the high-speed, precision cuts combined with lower costs, plasma cutting sees widespread use from large-scale industrial CNC applications down to small hobby shops.

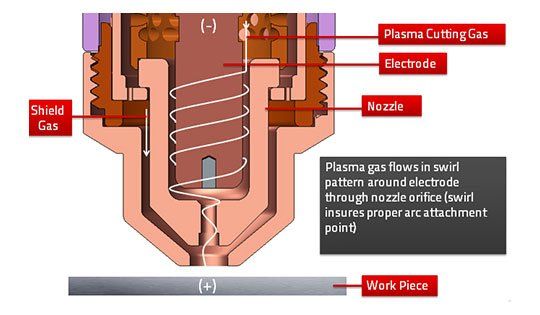

The basic plasma cutting process involves creating an electrical channel of super-heated, electrically ionized gas such as plasma from the plasma cutter itself through the work piece to be cut, thus forming a completed electric circuit back to the plasma cutter through a grounding clamp. This is accomplished by a compressed gas (oxygen, air, inert and others depending on material being cut) blown through a focused nozzle at high speed toward the work piece.

An electrical arc is then formed within the gas between an electrode near or integrated into the gas nozzle and the work piece itself. The electrical arc ionizes some of the gas, thereby creating an electrically conductive channel of plasma. As electricity from the cutter torch travels down this plasma, it delivers sufficient heat to melt through the work piece. At the same time, much of the high-velocity plasma and compressed gas blow the hot molten metal away, thereby separating or cutting through the work piece.

Benefits of Plasma Cutting

- Speed – Plasma cutters are up to five times faster than traditional, manual torches and are able to cut up to 500 inches per minute.

- Wider Ranges – Plasma cutting machines gives a wide range of precise cuts in a variety of materials and thickness. These plasma cutters utilize nitrogen, which enables them to cut not only steel but aluminum and other metals.

- Ease of Use – Plasma cutters require minimal training, making them user-friendly.

- Multi-Tasking – Plasma cutting machines are not just limited to cutting. They can be used as gauges to line up material perfectly.

- Safety – This cutting application uses nitrogen gas that is not highly flammable, reducing some of the safety hazards with gas cutting procedures.

- Economical – Plasma cutting is a cost-effective solution, less expensive than laser or water-jet cutting.

- Keeps Materials Cool – Despite operating at high temperatures, plasma cutting robotic systems can keep the surface of materials cool. This prevents warping and damage to paint and other coatings.

(516) 377-0428

Share On: